|

OTHER

IMPORTANT

INDUSTRIES IN

PATERSON

HOLLAND

SUBMARINES HOLLAND

SUBMARINES

John Philip Holland designed and tested his first submarines in Paterson.

The Holland I was fabricated at an iron works in New York City then moved to the J. C. Todd and Company

machine shop in Paterson in 1878. Here, a petroleum engine was installed for propulsion. The sub

measured 14 feet long. Trial runs were conducted in the Passaic River above the Great Falls. The boat

reached a depth of 12 feet and traveled at a speed of 3 1/2 miles per hour. The maximum submergence time

was about one hour.

Holland made many advances in submarine design, experimenting with

compressed air, steam and electricity as means of propulsion. Six of his submarines were built

altogether. The second Holland submarine, the Fenian Ram, was launched in 1881. It was a three-man boat

and made dives in excess of 45 feet. The last Holland submarine, the Holland VI, built in 1897, became

the first vessel in the U.S. Naval Submarine Fleet, commissioned as the U.S.S. Holland. This was a major

breakthrough in submarine design. For the first time, all the major components of submarine design were

present in one vessel - dual propulsion systems, a fixed longitudinal center of gravity, separate main

and auxiliary ballast systems, a hydrodynamically advanced shape, and a modern weapons system. It used a

gasoline engine while running on the surface and an electric motor while submerged. At top surface

speed, it could reach a speed of seven knots. Its length was 53 feet long. It had a range of 1000 miles

on the surface and 30 miles submerged.

Click here for excerpts from the Great Falls Visitor Center's Historic

Notes: The

Invention of Holland's Submarine.

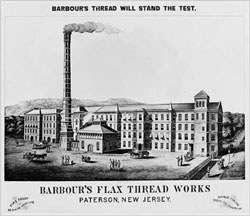

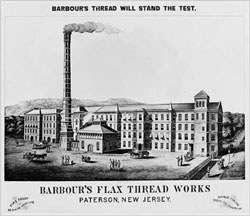

BARBOUR'S

FLAX THREAD WORKS BARBOUR'S

FLAX THREAD WORKS

Excerpts

from the NPS HAER

Report NJ-11:

The Barbour Flax

Spinning Company

was one of the

largest linen

works in the

country in the

second half of the

19th century,

employing some 440

people to process

over a million and

a half pounds of

flax

annually.

Thomas Barbour,

sent by his family

from Ireland to

establish an

American branch of

the family's

prosperous linen

thread company,

bought Passaic

Mill #2 in 1864

for $60,000.

He simultaneously

acquired the

rights to the two

square feet of

water deeded to

the lot and in

1865, leased an

additional

288" from the

S.U.M.

Rechristened the

"Belfast

Mill", the

building was

reoutfitted for

the production of

linen thread and

yarn.

Power

for the linen

works was supplied

by water from the

upper canal, and

by 1870, 120

horsepower was

being delivered

from a 54"

turbine

wheel. That

year, 40 men, 200

women, and 200

children tended

Barbour spindles,

processing

1,508,00 pounds of

Irish flax into

792,000 pounds of

machine thread,

150,000 pounds of

tailer's thread

and 20,000 pounds

of linen twines.

THE

PHOENIX MILL

Joachim

Velasquez, a

wealthy Mexican

who was living in

New York City,

founded the

Phoenix Mill in

1815. The mill

produced

candlewick and

cotton, later

switching to linen

and flax

production. In

1860, Benjamin

Tilt began silk

production on the

top floor of the

factory, and by

1865 he controlled

the entire

structure,

converting it from

cotton production

to silk. In the

1880s, the Phoenix

Company employed

8,000 people and

had 500 looms.

Click

here for excerpts

from the NPS HAER

REPORT NO. NJ-4: Phoenix Mill, Van Houten and Cianci Streets

THE

DOLPHIN JUTE

COMPANY

The

Dolphin Jute

Company,

established in

1844, converted

hemp and jute into

twine, rope and

carpet backing.

One of Paterson's

largest mills, it

encompassed 17

buildings.

THE

FRANKLIN MILL

The

Franklin Mill,

earlier known as

the old "Red

Mill," was

burned and rebuilt

several times. The

current building

was constructed in

1870 and expanded

in 1915. It was

used to produce

cotton yarn, silk,

steam fire

engines, brass

domes for

locomotives, and

other machinery.

Within the past

decade, it has

been restored as

an office complex.

THE

ESSEX MILL

The

Essex Mill

occupies the site

that was the first

to be leased from

the S.U.M.

The current

building contains

a portion of the

original

"Yellow

Mill,"

which was built in

1807.

Charles Kinsey,

the first tenant

of this mill,

conducted one of

the earliest

attempts to

manufacture paper

using a continuous

sheet process.

Over the years,

this building was

reconstructed and

expanded to

produce cotton,

mosquito netting

and silk. It has

recently been

restored into

government

subsidized housing

for artists and

musicians.

THE

LAMBERT MILL AND

DEXTER MILL THE

LAMBERT MILL AND

DEXTER MILL

Catholina

Lambert began work

as a ten-year-old

in a Yorkshire

cotton mill. At

seventeen, he was

an office boy in a

Boston silk firm,

Tilt &

Dexter. Two

years later, he

bought the shares

of a retiring

principal of the

firm and renamed

the company

Dexter, Lambert,

and Company.

He eventually

relocated it to

Paterson and by

1890, he was one

of the largest

mill owners in

Paterson.

There he made

enough money from

his five mills

(including two in

Pennsylavania) to

pay for the

English-style

castle he built on

Garret Mountain

and also for his

collection of some

400 original

paintings by

Renoir, Monet,

Courbet,

Rembrandt, and

others.

The

Silk Strike of

1913 put a great

strain on the silk

manufacturing

business.

Despite Lambert's

vast private

wealth, or perhaps

because of it (so

much of his income

had been spent in

economically

nonproductive

ways), he could

not recover from

the strike and was

forced to declare

bankruptcy.

His famous art

collection was

auctioned by the

American Art

Galleries in the

Grand Ballroom of

New York's Hotel

Plaza in

1916. The

sale of 365

paintings and

numerous

scupltures brought

him $592,050,

which was

estimated at about

one-third of the

real value.

Today, the Lambert Castle Museum is headquarters for the Passaic

County Historical Society and features gracious 19th century period rooms along with fascinating

exhibits relating to the history of Passaic County.

IVANHOE

PAPER

MANUFACTURING CO. IVANHOE

PAPER

MANUFACTURING CO.

One

of the most

extensive

industries in

Paterson was

carried out by the

Ivanhoe

Manufacturing

Company, which was

among the most

complete in the

world devoted to

paper production.

Henry V. Butler,

the founder of

this vast

establishment,

introduced the

process of boiling

stock under

pressure in rotary

boilers, a method

that was

universally

adopted throughout

this country and

in Europe. The

rope, cotton waste

and rags were

picked, cleansed,

boiled and

manipulated until

they left the mill

in the form of the

finest, whitest

writing paper.

In

1837, Roswell L.

Colt built a

substantial stone

mill, located on

the upper raceway,

especially for the

purposes of this

firm. The mill was

called the Passaic

Mill and it

furnished paper

for the most

foremost

publishers in the

country, including

the American Bible

Society, the

Methodist Book

concern, the

Appletons, Carter

Brothers and

others.

The

Ivanhoe Wheelhouse

was built in 1865

to house an

87-inch water

turbine that

supplied power to

the Ivanhoe

complex of ten

buildings. All of

the buildings are

gone now, except

for the

wheelhouse, which

was recently

restored. It sits

next to the

spillway between

the upper and

middle raceway.

Click

here for excerpts

from the

Great Falls

Visitor Center'sHistoric

Notes: The Ivanhoe Wheelhouse

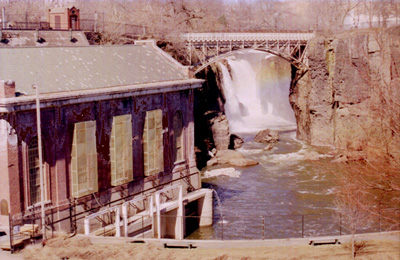

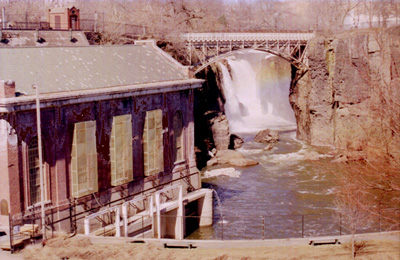

HYDROELECTRIC

POWER HYDROELECTRIC

POWER

In 1910, the

S.U.M. developed

plans to build a

hydroelectric

station at the

Great Falls to

replace the

waterpower from

the raceway. The

station had a

maximum capacity

of 6500

horsepower, with

its four huge

turbines

generating 21

million kilowatts

per year. It

operated from 1914

to 1969, at which

time the plant was

damaged by a

flood. Through

interest in

renewal, this

plant has been

restored to

working order. It

went back on line

December 31, 1986

and an overhaul on

the turbines was

started in October

1999.

Waterpower systems

use an energy

source that is

free. They do not

pollute and do not

use up the energy

source, but return

it unchanged to

the river.

Compared to fossil

fuels, they are

very efficient.

One disadvantage

to waterpower is

the reduction in

flowing water

caused by

droughts. However,

as fossil fuels

become more

costly, small

hydroelectric

sites, like the

one at the Great

Falls, are

becoming more

attractive.

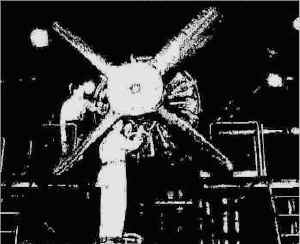

CURTISS-WRIGHT CORPORATION CURTISS-WRIGHT CORPORATION

During

World War II,

Paterson became a

major center of

Curtiss-Wright

engine production.

In 1920, the

Wright

Aeronautical

Corporation

designed and built

the Whirlwind and

Cyclone aircraft

engines, which

made aviation

history. In 1927

Charles Lindberg

had a 200

Horsepower J-1

air-cooled

Whirlwind Engine

custom-made for

his historic solo

Trans-Atlantic

flight. Through

the 1930's and

40's, the

company employed

as many as 25,000

workers and

manufactured over

120,000 various

types of aircraft.

It was during this

period of time

that Paterson was

called "The

Aviation City".

The

Curtiss-Wright

Corporation had a lot of

history in early

aviation with the

Wright in the name

coming from the

Wright Brothers.

This company was

of significant

importance to the

outcome of WWII.

They manufactured

the P 40 Warhawk

Fighter, C 46

Commando Cargo

Transport, SB2C

Helldiver Navy

Bomber, Army A 25

Helldiver, Seagull

Navy Scout Plane

and the Republic

Thunderbolt

Fighter.

|

HOLLAND

SUBMARINES

HOLLAND

SUBMARINES  BARBOUR'S

FLAX THREAD WORKS

BARBOUR'S

FLAX THREAD WORKS

THE

LAMBERT MILL AND

DEXTER MILL

THE

LAMBERT MILL AND

DEXTER MILL IVANHOE

PAPER

MANUFACTURING CO.

IVANHOE

PAPER

MANUFACTURING CO. HYDROELECTRIC

POWER

HYDROELECTRIC

POWER CURTISS-WRIGHT CORPORATION

CURTISS-WRIGHT CORPORATION